The micronizing mill is a state-of-the-art machine designed and manufactured for micropulverizing various materials. This system is specifically designed for micrometer powder processing of materials with high performance and high precision.

The range of micronizer mill applications includes:

- Minerals: calcium carbonate, gypsum, and others

- Chemicals: PVC, resins, and others

- Plant products: vanilla, cocoa, and others

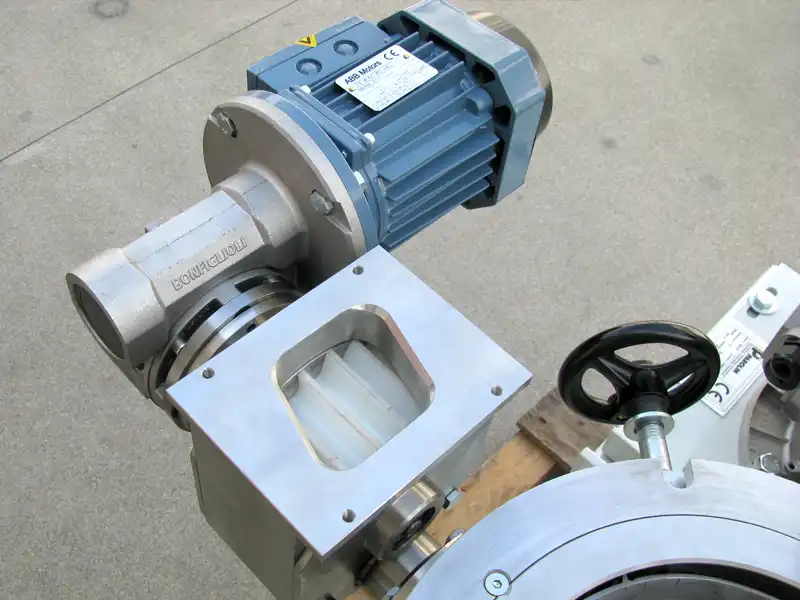

The operation of the mill is based on impact and friction technology, which ensures the production of uniform and high-quality powder. The controlled dosing system allows you to adjust the amount of material to be ground, and the dynamic variable-speed selector classifies the powder according to the desired micrometer size.

The dust produced is collected in a cyclone and discharged continuously by a rotocell. The outgoing air is then cleaned and recycled through a suitable bag filter. The pulverization chamber of the mill is equipped with an interspace for cooling by circulating water or nitrogen.

The main features of the micronizing mill include:

- Ease of cleaning by quickly opening the various components

- High performance and precision in powder production

- Wide range of applications