These types of mills, designed and manufactured by us, are used for grinding different types of materials.

Some types of materials commonly affected are:

- Minerals (calcium carbonate, gypsum, etc.).

- Chemicals (pvc, different types of resins, etc.).

- Vegetable products (vanilla, cocoa, other types of dried vegetables and cereals)

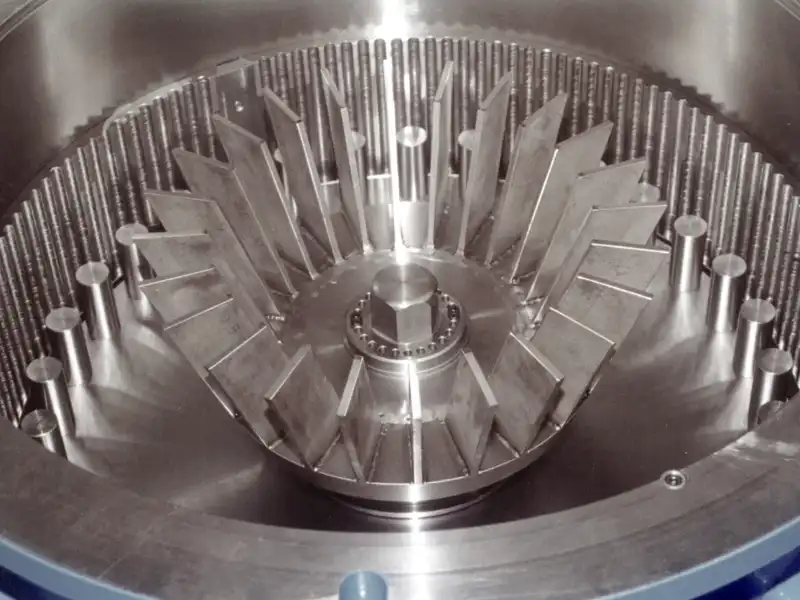

The principle of operation of MICRONIZER mills is based on the impact and rubbing of materials fed with dosing system, between special pegs mounted on the impeller and the inner chamber jacket of the mill itself.

A dynamic variable speed selector classifies the powder into the desired micrometer size.

The powder is collected in a cyclone and discharged continuously through a rotocell.

The outgoing air is cleaned and recycled through a suitable bag filter.

The spray chamber is equipped with a cavity for cooling by circulating water or nitrogen.

Key features include ease of cleaning by quickly opening the mill, classifier, piping and cyclone.